this is to answer a few questions for the auto to manual swap. i'm not trying to make this a full write up at all, just some helpful info, but i'd still like to keep this thread really clean and informative. so that's try to keep it that way. i just recently helped someone on here with a few things so i figured i'd post it here and try to get some of these thing in one place. for people who have all reedy done this feel free to post things/tricks you know. and i'll copy it to the first page.

1'st if your gonna be doing this get the helms manual. with just that you can do the entire swap. so in other words YOU NEED THE HELMS!!!

clutch line + damner ect:

you don't need all this stuff just run a SS braided line from the master to the slave cylinder.

(i got mine at a place near me but you should be able to order it from many places online. just measure out the length you need and i believe it's a 4-an fitting but it may be a 3-an, so check first. and measure twice before you order.)

also alpinefr3ak has shown that you can use a clutch line from a 93 civic.

getting the car to start + wiring your reverse lights:

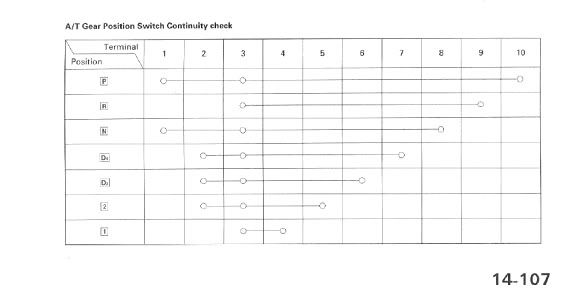

find the AT gear position switch connector that used to go to your AT transmission. its a ten terminal connector

you need to connect #3 & #1 together so that the car will start and you need to connect #3 & #9 to the reverse switch on the manual trans so that your reverse lights work. (polarity doesn't matter, and i suggest getting bullet connectors from your local hardware store so you don't need to cut them for a clutch change.)

![Image]()

![Image]()

Auto to manual ECU conversion

(in case you don't want to replace your ecu. i did not wright this but have heard it works.)

http://honda-tech.com/zerothread?id=1275452

Reinforcing the clutch pedal/bracket:

*reinforcing the clutch pedal will be up soon as possible.

here is the bracket that you need to cut off from a manual lude or make yourself. here's picks of it installed. i got it from prelude1987 and when he removed it, to remove it, he drilled out the spot welds(2) i used those, plus i drilled two more holes and used a total of 4 fat, but short, sheet metal screws. bolts or rivets would be nice but unless you feel like removing your whole dash it won't happen, that would be the only way to get to the other side. that's why i just used screws. having it welded on would also be a nice way to go, but i doubt any welder would be willing to try to work under there and they would probably melt some important wires if they tried. heres the picks:

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

disregard the extra hole you see (installed it a little off) and the slit. you wont have those. the phillips screws are the ones were the spot welds were. first i widened the holes of where the spot welds were and then i drilled into the under side of the dash two corresponding holes, the holes in the dash i drilled just smaller then the screws i was using. that way with just those two screws installed i could move it slightly to get it just right. once it was in the right spot i tightened those down, then screwed in two more (the flat heads.)

well there it is guys, thats the bracket and soon hopefully i will have up pics of the reenforcement to the firewall, although this bracket is all you really need. because of the way it's setup using leverage, this little bracket probably takes 98% of the force applied as were the reenforcement takes the other 2%, actually the only reason i did reinforce my firewall is because originally the shop that did my swap installed the clutch pedal wrong. and so theres alot of extra holes in the firewall weakening it alot. it wouldn't break, but I'm pretty anal about having flex in the pedal.

Also guys some of you are going to have to make that bracket yourselves, so i really hope when one of you does they let me know. take pic/write how it was done and post it here or pm me. Then i'll post/move it to the first page.

1'st if your gonna be doing this get the helms manual. with just that you can do the entire swap. so in other words YOU NEED THE HELMS!!!

clutch line + damner ect:

you don't need all this stuff just run a SS braided line from the master to the slave cylinder.

(i got mine at a place near me but you should be able to order it from many places online. just measure out the length you need and i believe it's a 4-an fitting but it may be a 3-an, so check first. and measure twice before you order.)

also alpinefr3ak has shown that you can use a clutch line from a 93 civic.

getting the car to start + wiring your reverse lights:

find the AT gear position switch connector that used to go to your AT transmission. its a ten terminal connector

you need to connect #3 & #1 together so that the car will start and you need to connect #3 & #9 to the reverse switch on the manual trans so that your reverse lights work. (polarity doesn't matter, and i suggest getting bullet connectors from your local hardware store so you don't need to cut them for a clutch change.)

Auto to manual ECU conversion

(in case you don't want to replace your ecu. i did not wright this but have heard it works.)

http://honda-tech.com/zerothread?id=1275452

Reinforcing the clutch pedal/bracket:

*reinforcing the clutch pedal will be up soon as possible.

here is the bracket that you need to cut off from a manual lude or make yourself. here's picks of it installed. i got it from prelude1987 and when he removed it, to remove it, he drilled out the spot welds(2) i used those, plus i drilled two more holes and used a total of 4 fat, but short, sheet metal screws. bolts or rivets would be nice but unless you feel like removing your whole dash it won't happen, that would be the only way to get to the other side. that's why i just used screws. having it welded on would also be a nice way to go, but i doubt any welder would be willing to try to work under there and they would probably melt some important wires if they tried. heres the picks:

disregard the extra hole you see (installed it a little off) and the slit. you wont have those. the phillips screws are the ones were the spot welds were. first i widened the holes of where the spot welds were and then i drilled into the under side of the dash two corresponding holes, the holes in the dash i drilled just smaller then the screws i was using. that way with just those two screws installed i could move it slightly to get it just right. once it was in the right spot i tightened those down, then screwed in two more (the flat heads.)

well there it is guys, thats the bracket and soon hopefully i will have up pics of the reenforcement to the firewall, although this bracket is all you really need. because of the way it's setup using leverage, this little bracket probably takes 98% of the force applied as were the reenforcement takes the other 2%, actually the only reason i did reinforce my firewall is because originally the shop that did my swap installed the clutch pedal wrong. and so theres alot of extra holes in the firewall weakening it alot. it wouldn't break, but I'm pretty anal about having flex in the pedal.

Also guys some of you are going to have to make that bracket yourselves, so i really hope when one of you does they let me know. take pic/write how it was done and post it here or pm me. Then i'll post/move it to the first page.