ok, so i finally got around to determining the exact specs of our stock camshafts. i accomplished this with the use of an 18 inch moroso degree wheel, a digital micrometer with depth function (clamped to head tightly, spaced with hard cardboard to get the right angle (perfectly parallel to valve)), a strip of exhaust hanger for a pointer bolted to the t-belt cover bolt near the motor mount, my nifty engine stand, a b21 block, a b21 head, b21 crank, and b21 auto flywheel (5spd flywheel wont fit while mounted to the stand.) mounted flywheel so i could perfectly set the pointer to TDC according to the mark on the fly. no pistons or rods were installed, also to decrease rotational friction of the crank. when the crank is being turned so extremely slowly, any amount of unnecessary friction will cause it to bind and jump, instead of turning smoothly at those massively low speeds.

as for the way i set the motor up, i only installed rockers for each cam for the number 1 cylinder. no rockers in any other cyl. means much less resistance for turning the crank. all bearing surfaces were cleaned and oiled with fresh oil, bearings are from a used motor but within specs according to the manual. a few cc's of oil was dripped onto all cam bearing surfaces before caps were put on. a few cc's of oil was dripped onto each cam lobe for cyl 1. timing belt was set extremely tight by pushing very hard on the tensioner as i tightened the tensioner bolt. the 4 rockers were adjusted to 0.0005-0.0010 inches of clearance, to simulate a warmed up motor.

the b20a5 cams have about 80k miles on them

the b21a1 cams have about 117k miles on them

the head has never been shaved at all, block has never been shaved at all, and the block to head clearance (HG thickness) was set to 1.200mm (stock HG thickness when crushed under proper torque). this thickness was achieved by the use of a double layer of make-a-gasket intake gasket material. uncrushed it is 0.8mm thick, doubled up 1.6mm. crushed under proper torque worked out perfectly to 1.2mm.

i determined exact timing at lifts of: 0.010", 0.020", 0.030", 0.040", and the universal 0.050".

i also determined exact lift accurate to within 0.0005" for every 5 degrees between the above lift open and close points

i also determined exact timing of max lift. which is also known as the lobe center.

i did the entire process twice per valve to guarantee no mistakes, or variations in results. 2 cams, 2 valves per cam = 4 valves. twice per valve, means i ran this entire process 8 times. never was there any variations in numbers between any of the 8 processes. so you can be assured all numbers are 100% accurate.

i have all exact lift measurements for each cam in seperate microsoft excel files, along with the original graphs. if anyone would like me to transfer the excel documents containing all the actual numbers and information to them, please pm me through the site, or better yet send me an instant msg through aim/aol yahoo or msn via the little buttons/icons below my name to the left. i would be happy to share all info. putting all of the info in this thread would take quite a while, and take up an aweful lot of space for one post.

pics of the setup mid-progress. notice the sky blue lude without a rear bumper or bumper bracket off to the side? thats my project car, and probably the only pic of it most of you will see for quite a while :

:

![Image]()

![Image]()

ok, now on to the part you've all been waiting for, the specs.

ATDC = after top dead center

BTDC = before top dead center

TDC = top dead center

BDC = bottom dead center

all degree numbers are in crank degrees

all measurements were taken in inches

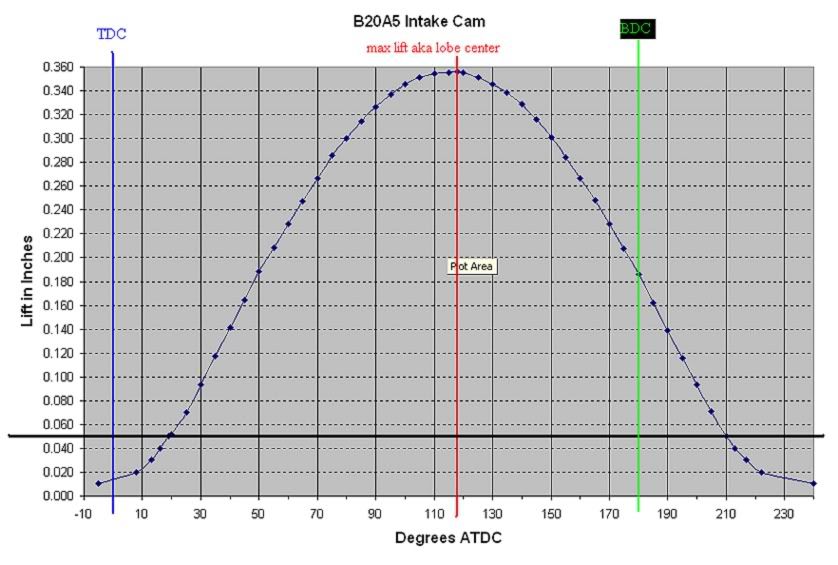

b20a5 cams:

intake cam:

open point: (@ the following lift at the valve)

0.010" 5.5 degrees BTDC

0.020" 8 degrees ATDC

0.030" 13 degrees ATDC

0.040" 16 degrees ATDC

0.050" 19 degrees ATDC

close point: (@ following lift at the valve)

0.010" 241 degrees ATDC

0.020" 222 degrees ATDC

0.030" 217 degrees ATDC

0.040" 213 degrees ATDC

0.050" 210 degrees ATDC

duration (@ following lift at the valve)

0.010" 246.5 degrees

0.020" 214 degrees

0.030" 204 degrees

0.040" 197 degrees

0.050" 191 degrees

max lift:

0.356" @ 118 degrees ATDC

0.209" lobe lift

lobe center:

114.5 degrees ATDC

valve lift @TDC:

0.0135"

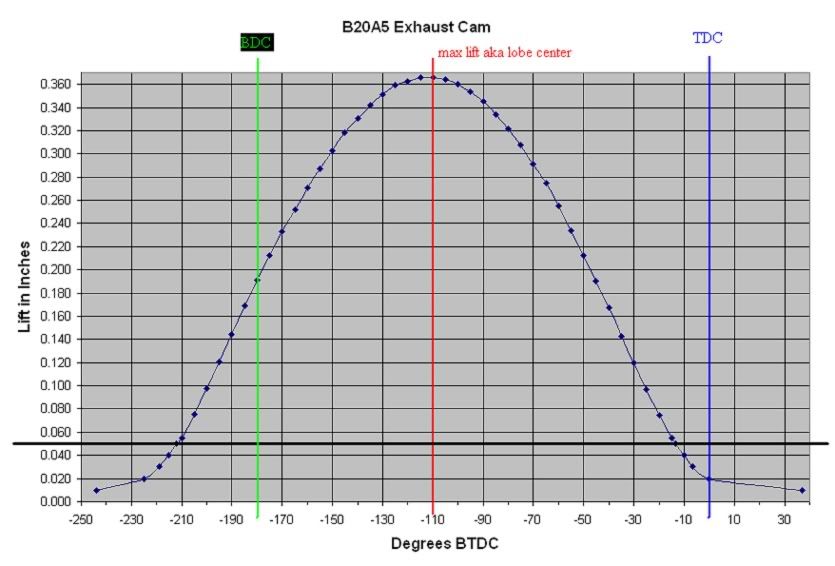

exhaust cam:

open point: (@ following lift at the valve)

0.010" 244 degrees BTDC

0.020" 225 degrees BTDC

0.030" 219 degrees BTDC

0.040" 215 degrees BTDC

0.050" 212 degrees BTDC

close point: (@ following lift at the valve)

0.010" 37 degrees ATDC

0.020" 0 degrees, perfect TDC

0.030" 6.5 degrees BTDC

0.040" 10 degrees BTDC

0.050" 13.5 degrees BTDC

duration (@ following lift at the valve)

0.010" 281 degrees

0.020" 225 degrees

0.030" 212.5 degrees

0.040" 205 degrees

0.050" 198.5 degrees

max lift:

0.366" @110 degrees BTDC

0.215" lobe lift

lobe center:

113 degrees BTDC

valve lift @TDC:

0.020"

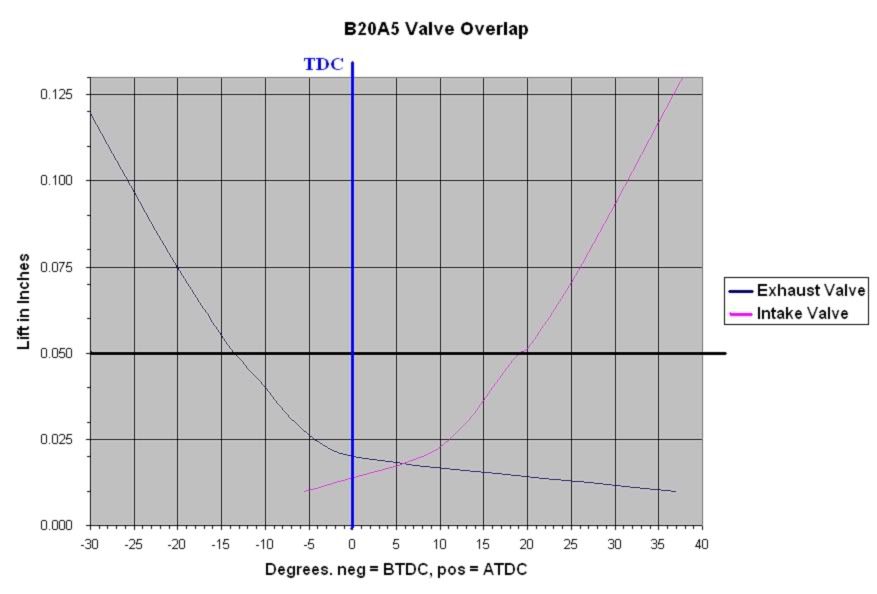

valve overlap: (@ following lift at the valve)

0.010" 42.5 degrees

0.020" negative 8 degrees

0.030" negative 19.5 degrees

0.040" negative 26 degrees

0.050" NEGATIVE 32.5 degrees!!! (HOLY FRICKIN CRAP MAN!!!! THIS VALVE TIMNG BLOWS MAJOR BUTTHOLE!!!!!)

here are graphs of all data points collected. the concept of these graphs is to as best as possible portray the profile of the cam lobes. again, if you would like the actual microsoft excel documents containing all actual information (tables and graphs) contact me and i'd be happy to send them to you:

the thick horizontal black line is the marker for the universal open/close point at 0.050" lift

left side of each graph is where valve begins to open, right side is where valve closes.

dont mind the negative numbers in the exhaust graph, it's the only way i could get the data to line up properly in the graph.

to the left if the blue TDC line is degrees BTDC, to the right of the blue TDC line is degrees ATDC, for both graphs. 0 degrees = TDC

if you're unable to read it, the red line is "max lift aka lobe center", blue line is "TDC", green line is "BDC"

![Image]()

![Image]()

![Image]()

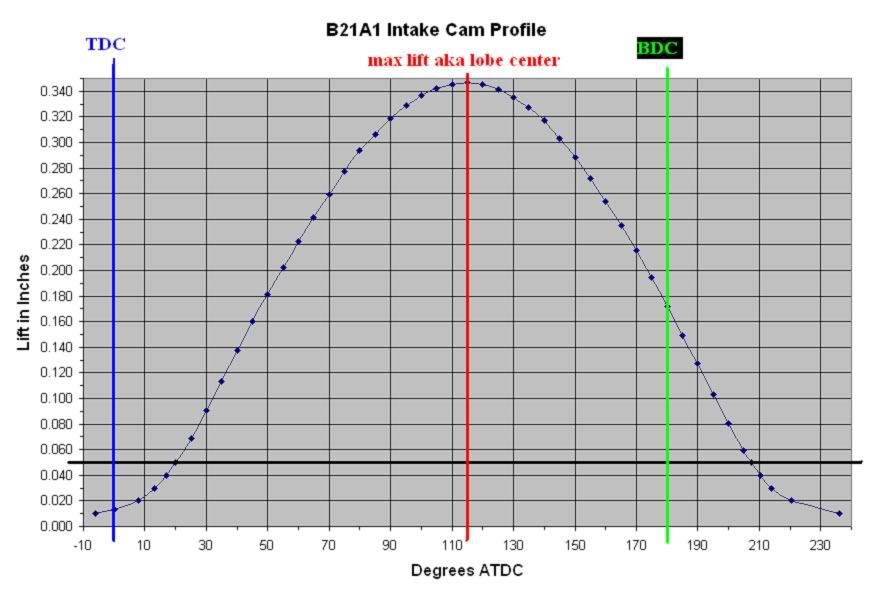

b21a1 cams:

intake cam:

open point @ following lift at the valve:

0.010" 6 degrees BTDC

0.020" 8 degrees ATDC

0.030" 13 degrees ATDC

0.040" 17 degrees ATDC

0.050" 20 degrees ATDC

close point: @ following lift at the valve

0.010" 236 degrees ATDC

0.020" 220.5 degrees ATDC

0.030" 214 degrees ATDC

0.040" 210.5 degrees ATDC

0.050" 207.5 degrees ATDC

duration: @ following lift at the valve

0.010" 242 degrees

0.020" 212.5 degrees

0.030" 201 degrees

0.040" 193.5 degrees

0.050" 187.5 degrees

max lift:

0.3465" @ 115 degrees ATDC

0.204" lobe lift

lobe center:

114 degrees ATDC

valve lift at TDC:

0.013"

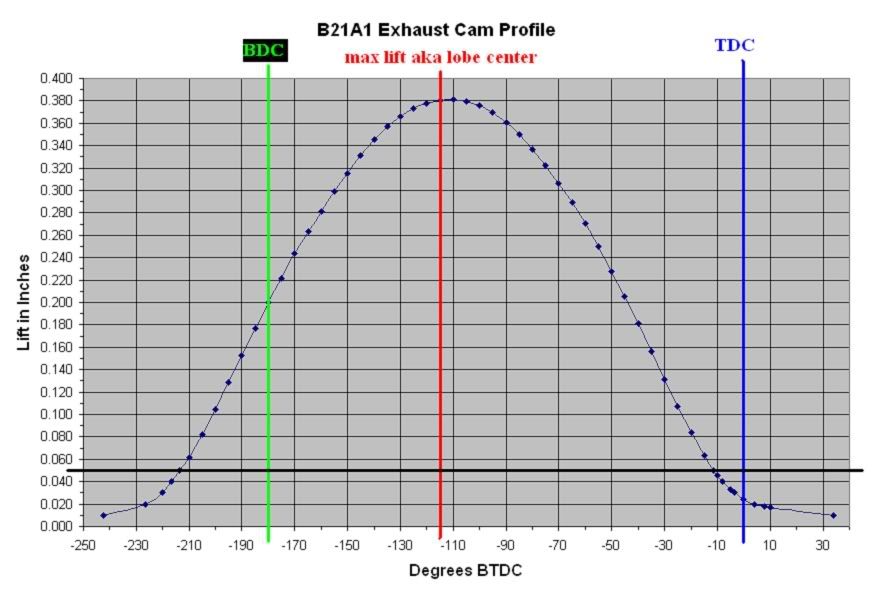

exhaust cam:

open point: @ following lift at the valve

0.010" 242.5 degrees BTDC

0.020" 226.5 degrees BTDC

0.030" 220 degrees BTDC

0.040" 216.5 degrees BTDC

0.050" 213.5 degrees BTDC

close point: @ following lift at the valve

0.010" 34 degrees ATDC

0.020" 4 degrees ATDC

0.030" 3.5 degrees BTDC

0.040" 8 degrees BTDC

0.050" 11.5 degrees BTDC

duration: @ following lift at the valve

0.010" 276.5 degrees

0.020" 230.5 degrees

0.030" 216.5 degrees

0.040" 208.5 degres

0.050" 202 degrees

max lift:

0.3815" @110 degrees BTDC

0.224" lobe lift

lobe center:

112.5 degrees BTDC

valve lift at TDC:

0.024"

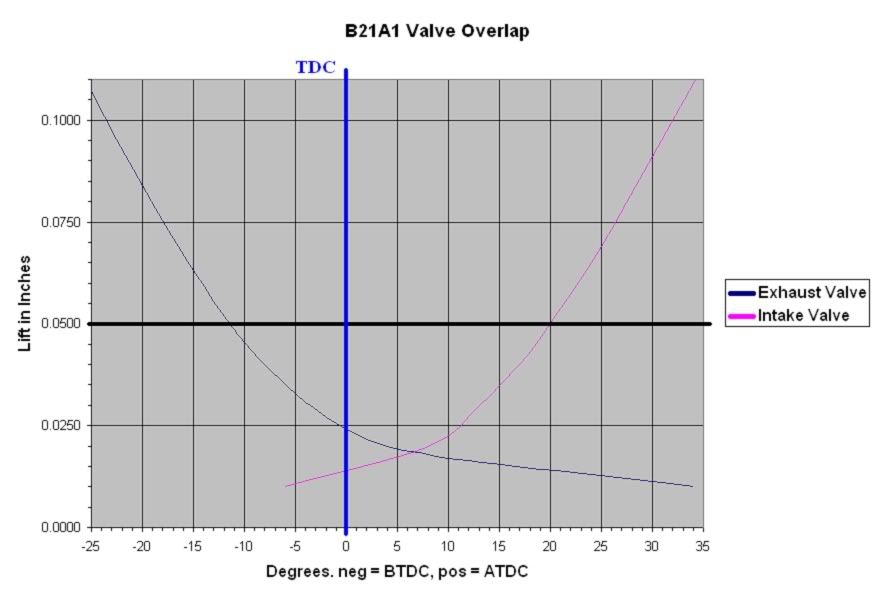

valve overlap: (@ following lift at the valve)

0.010" 40 degrees

0.020" 4 degrees

0.030" NEGATIVE 16.5 degrees

0.040" NEGATIVE 25 degrees

0.050" NEGATIVE 31.5 degrees

now for the graphs of the lift of each b21 cam:

the thick horizontal black line is the marker for the universal open/close point at 0.050" lift

left side of each graph is where valve begins to open, right side is where valve closes.

dont mind the negative numbers in the exhaust graph, it's the only way i could get the data to line up properly in the graph.

to the left if the blue TDC line is degrees BTDC, to the right of the blue TDC line is degrees ATDC, for both graphs. 0 degrees = TDC

![Image]()

![Image]()

![Image]()

b18b1 cams:

intake cam:

open point: (@ the following lift at the valve)

0.010" 2 degrees BTDC

0.020" 10 degrees ATDC

0.030" 14.5 degrees ATDC

0.040" 18 degrees ATDC

0.050" 20 degrees ATDC

close point: (@ following lift at the valve)

0.010" 242 degrees ATDC

0.020" 225 degrees ATDC

0.030" 220 degrees ATDC

0.040" 216 degrees ATDC

0.050" 213.5 degrees ATDC

duration (@ following lift at the valve)

0.010" 244 degrees

0.020" 215 degrees

0.030" 205.5 degrees

0.040" 198 degrees

0.050" 193.5 degrees

max lift:

0.388" @ 118 degrees ATDC

0.228" lobe lift

lobe center:

117 degrees ATDC

valve lift @TDC:

0.012"

exhaust cam:

open point: (@ following lift at the valve)

0.010" 259 degrees BTDC

0.020" 225 degrees BTDC

0.030" 219 degrees BTDC

0.040" 215 degrees BTDC

0.050" 212 degrees BTDC

close point: (@ following lift at the valve)

0.010" 15 degrees ATDC

0.020" 6 degrees BTDC

0.030" 12 degrees BTDC

0.040" 15 degrees BTDC

0.050" 18.5 degrees BTDC

duration (@ following lift at the valve)

0.010" 274 degrees

0.020" 219 degrees

0.030" 207 degrees

0.040" 200 degrees

0.050" 193.5 degrees

max lift:

0.3485" @115 degrees BTDC

0.205" lobe lift

lobe center:

115 degrees BTDC

valve lift @TDC:

0.017"

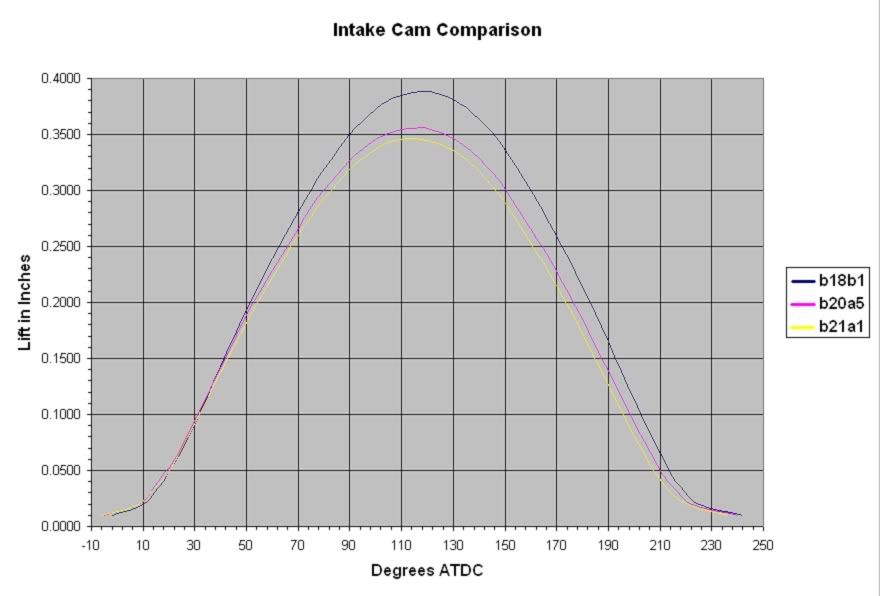

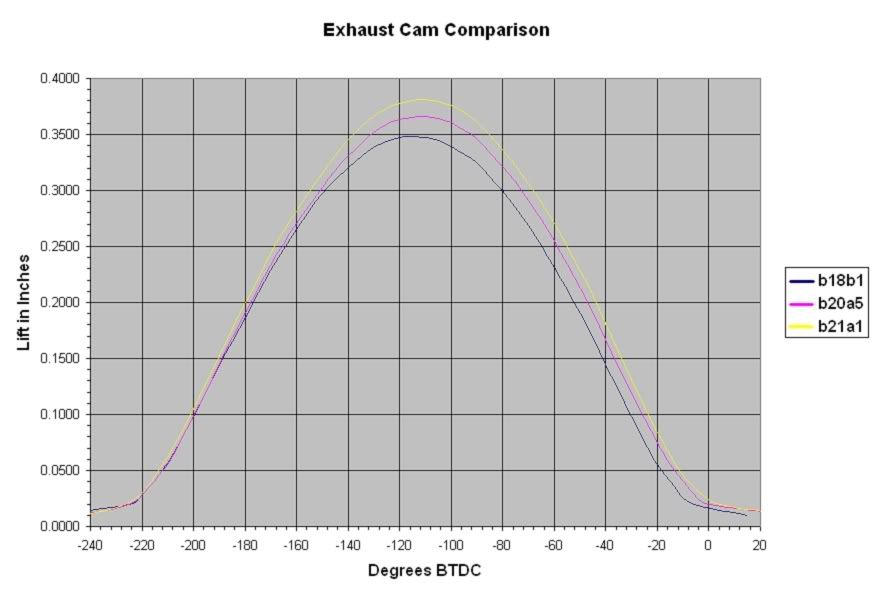

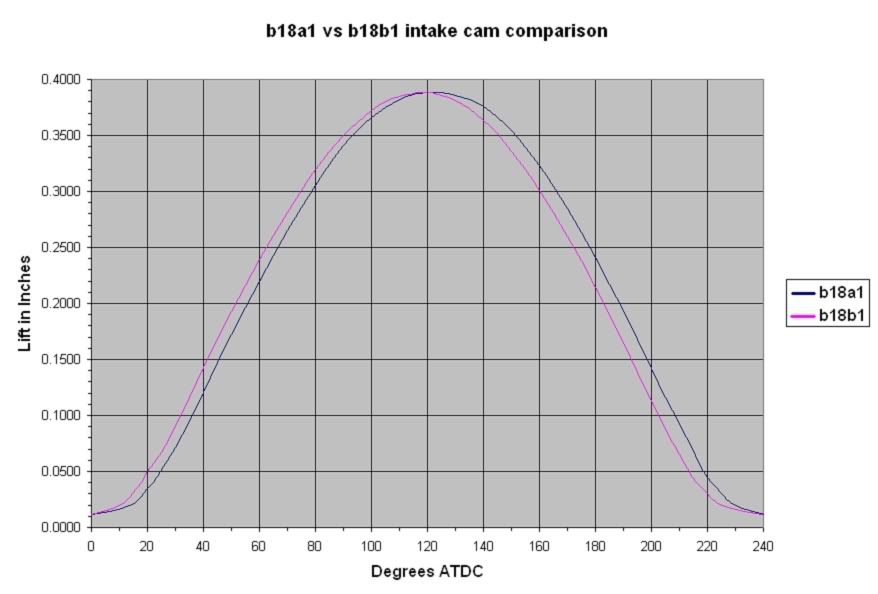

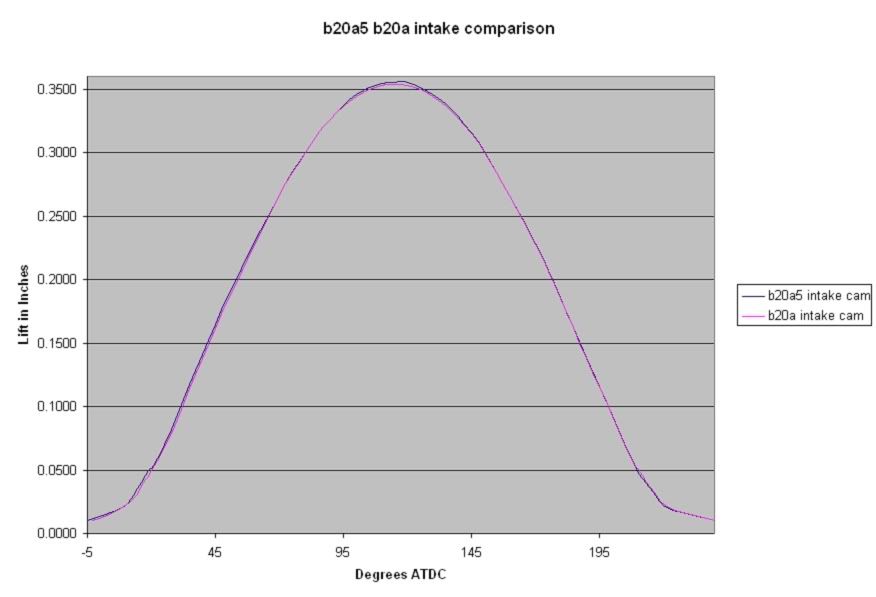

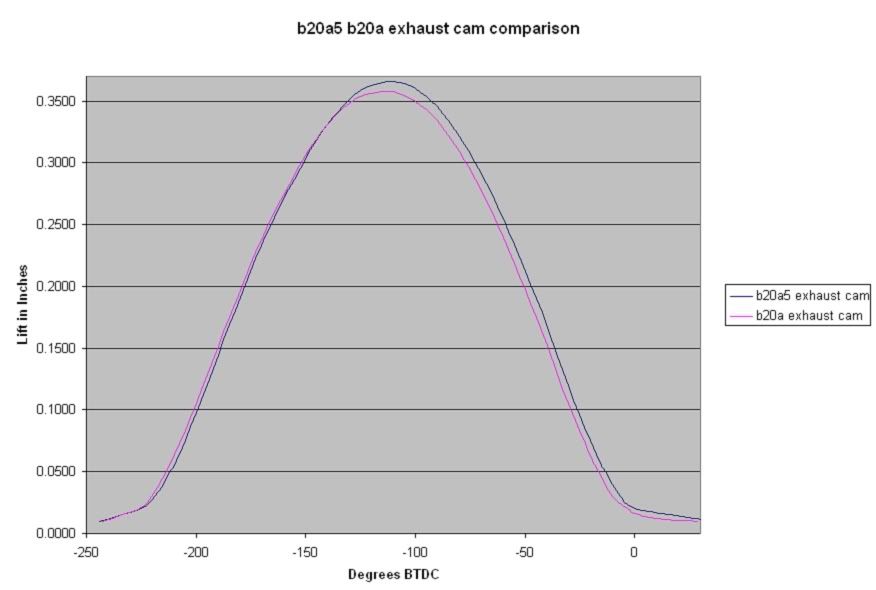

now on to the fun part, the comparison of each cam. the following are graphs on the cams together so you can see the direct relation of one to the other.

notice how the b20a5 intake cam has ever so slightly more lift then the b21a1 cam throughout the duration, but about the same duration time length.

also notice the b21a1 exhaust cam has a decent amount more lift then the b20a5 exhaust cam throughout the duration, and a slightly noticeable longer duration then the b20a5 exhaust cam.

the graph makes it easier to see. and even though it doesnt look like too too much in the graph, in cam terms, the difference performance-wise is fairly considerable.

removed the old comparison graphs, and added these new ones that include all 3 cams in each graph. i think the graphs speak for themselves. enjoy!!!

![Image]()

![Image]()

b18a1 cams:

today i got all the same data on b18a1 cams. i got a few basic specs on the b18a1 exhaust cam and it is almost identical to the b20a5 exhaust cam, so it would be pointless to get all data and graph it and compare it and everything else. and at the cost to modify a b18 exhaust cam to fit our motors, it's really pointless. so no major data was collected for the b18a1 exhaust cam, and no graphs were created.

the b18a1 intake cam is 99.9% identical to the b18b1 intake cam, except the fact that the entire lobe is shifted about 5 degrees. in other words, all duration and lift specs are identical between the b18a1 and b18b1 intake cam, but the b18b1 intake cam is advanced 5 crank degrees more than the b18a1 intake cam.

this means that you can use a b18a1 or a b18b1 intake cam in your 3g and get about the same results. if you get a b18a1 intake cam, it would be a good idea to get adjustable cam gears to advance it to get it even with a b18b1 cam, or advance it further to aim towards a little more overlap. aka not so far into the negatives lmao. to get the b18a1 cam even with the b18b1 cam as far as exact timing, you would set the cam gear to +2.5, because 2.5 cam degrees equals 5 crank degrees.

here is a comparison graph of the b18a1 and b18b1 intake cams to display the exact specs on both cams. i think the graph is pretty self explanatory.

![Image]()

b20a cams:

today i was able to get all the usual data on a set of jdm b20a cams, thanks to secluded luder for providing them for testing. i was shocked when i looked over the results, and especially shocked when i graphed them. well, kind of a mix between seeing what i expected for one, and something totally unexpected for the other. due to the graphic nature of this program viewer discretion is advised lmao! actually, due to the results of the data collected, im not going to bother posting the actual info on them as i have for the above other cams. to sum it up, the jdm b20a intake cam is 100% identical to the USDM b20a5 intake cam. the jdm b20a exhaust cam is similar to the b20a5 exhaust cam, but a bit worse. to further explain and see the similarities, simply lok at the following graphs; they show all:

sorry to disappoint you guys lol

![Image]()

![Image]()

b20a5 overlap:

(@ following lift at the valve)

0.010": 42.5 degrees

0.020": negative 8 degrees

0.030": negative 19.5 degrees

0.040": negative 26 degrees

0.050":negative 32.5 degrees

b20a5 overlap with gears set to +4/-4:

(@ following lift at the valve)

0.010": 58.5 degrees

0.020": 8 degrees

0.030": negative3.5 degrees

0.040": negative10 degrees

0.050":negative 16.5 degrees

b21a1 overlap:

(@ following lift at the valve)

0.010": 40 degrees

0.020": 4 degrees

0.030": negative 16.5 degrees

0.040": negative 25 degrees

0.050": negative 31.5 degrees

b21a1 overlap with gears set to +4/-4:

(@ following lift at the valve)

0.010": 56 degrees

0.020": 20 degrees

0.030": negative 0.5 degrees

0.040": negative 9 degrees

0.050": negative 15.5 degrees

b21 ex b20a5 int overlap:

(@ following lift at the valve)

0.010": 39.5 degrees

0.020": negative 4 degrees

0.030": negative 16.5 degrees

0.040": negative 24 degrees

0.050": negative 30.5 degrees

b21 ex b20a5 int overlap with gears set to +4/-4:

(@ following lift at the valve)

0.010": 55 degrees

0.020": 12 degrees

0.030": negative 0.5 degrees

0.040": negative 8 degrees

0.050": negative 14.5 degrees

b21 ex b18b int overlap:

@the following lifts at the valve:

0.010": 32 degrees

0.020": negative 6 degrees

0.030": negative 18 degrees

0.040": negative 26 degrees

0.050": negative 31.5 degrees

b21 ex b18b int overlap with gears set to +4/-4 in/ex:

@the following lifts at the valve:

0.010": 48 degrees

0.020": 10 degrees

0.030": negative 2 degrees

0.040": negative 10 degrees

0.050": negative 15.5 degrees

b21 ex b18a int overlap:

@the following lifts at the valve:

0.010": 36 degrees

0.020": negative 10 degrees

0.030": negative 22 degrees

0.040": negative 30 degrees

0.050": negative 36 degrees

b21 ex b18a int overlap with gears set to +4/-4 in/ex:

@the following lifts at the valve:

0.010": 52 degrees

0.020": 6 degrees

0.030": negative 6 degrees

0.040": negative 14 degrees

0.050": negative 20 degrees

suggested cam specs for regrinds:

keep in mind these figures are given with the lift point being at the valves, not at the cams. so these are not a direct translation to simply hand over to a re-grinder.

i will translate them into specs that you CAN simply hand to a re-grinder sometime in the near future i hope.

stage 0.5:

b20a5 intake cam

b21a1 exhaust cam

stage 0.9:

in: 193.5 degrees duration @ 0.050" valve lift, 0.388" max lift (b18b intake cam, uncertain for now)

ex: 202 degrees duration @ 0.050" valve lift, 0.382" max lift (b21a1 exhaust cam)

stage 1:

in: 201 degrees duration @ 0.050" valve lift, 0.400" max lift

ex: 202 degrees duration @ 0.050" valve lift, 0.382" max lift (b21a1 exhaust cam)

stage 2:

in: 198 degrees duration @ 0.050" valve lift, 0.415" max lift

ex: 203 degrees duration @ 0.050" valve lift, 0.405" max lift

stage 3:

in: 204 degrees duration @ 0.050" valve lift, 0.430" max lift

ex: 204 degrees duration @ 0.050" valve lift, 0.420" max lift

stage 4:

in: 208 degrees duration @ 0.050" valve lift, 0.440" max lift

ex: 206 degrees duration @ 0.050" valve lift, 0.430" max lift

i could create a stage 5 if anyone wants to know

turbo cams (any type of turbo setup):

in: 205 degrees duration @ 0.050" valve lift, 0.465" max lift

ex: 202 degrees duration @ 0.050" valve lift, 0.465" max lift

stage 2 is recommended for street and strip and various speed track racing.

stage 3 is suggested for all out racing (mostly higher speed track, and drag), but can be used on the street with some minor discomfort in typical driving situations at lower rpms, and may not idle at stock idle speeds. crap power below 3k, decent 3k-4500, great/wicked power 4500-7200

stage 4 is full out 100% race only; high speed only track racing, and all out drag. basically meaning that with stage 4 the engine will be tough to start initially, and it WILL NOT IDLE below 1500-2k or so; and you will have crap for power below 4500, good power 4500-~5800, and wicked power 5800-7200

i have officially determined max allowable lift at the valves with the stock valvetrain; aka springs and retainers.

maxed out at: 0.487"

my recommended max limit: 0.450"

my recommended max SAFE limit: 0.440"

so basically, if you want to go with more then 0.440" of lift i highly suggest you get aftermarket springs and retainers that will allow that much lift. if you want to go more then 0.450" of lift, you will NEED to get aftermarket springs and retainers that will allow that lift.

update: 1/04/08:

jdm b21a cams are practically identical to the usdm b21a1 cams i previously measured.

ludasaurus was kind enough to ship me a set of jdm b21a cams to spec.

im not gonna bother making charts and diagrams and everything for them cuz they are almost 100% identical to the usdm b21a1 cams. like 0.001" difference in valve lift at a couple random points, thats about the only difference, which is nothing, more than that could happen just from wear and/or user error

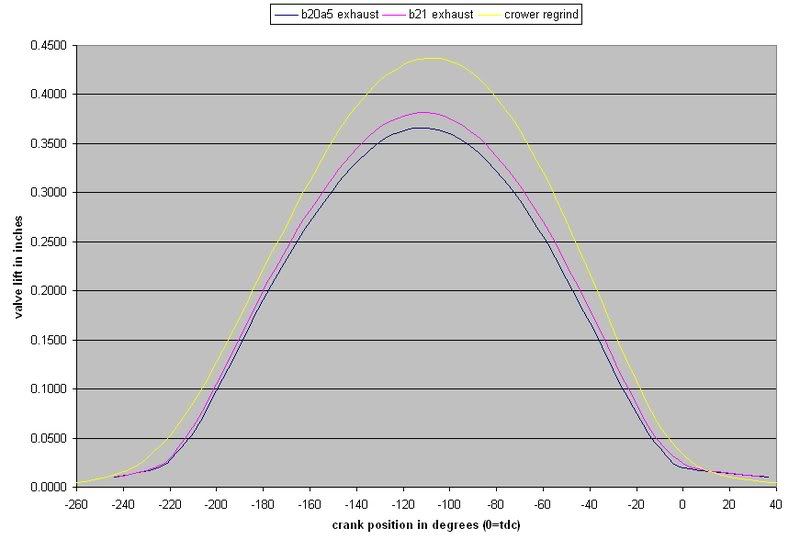

update 05/12/08:

i specc'ed and charted secluded luder's crower regrinds for the 3g prelude, which were discontinued a few years back. but here they are:

exhaust cam compared to b20a5 and b21a1 exhaust cams, all 3 spec'ed with stock cam gears:

![Image]()

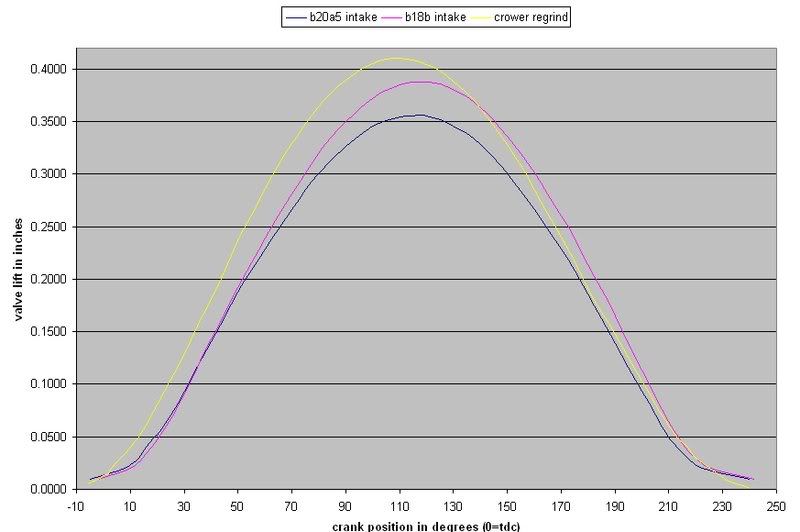

crower regrind intake cam compared to b20a5 intake cam and b18b intake cam, all spec'd with stock cam gears:

![Image]()

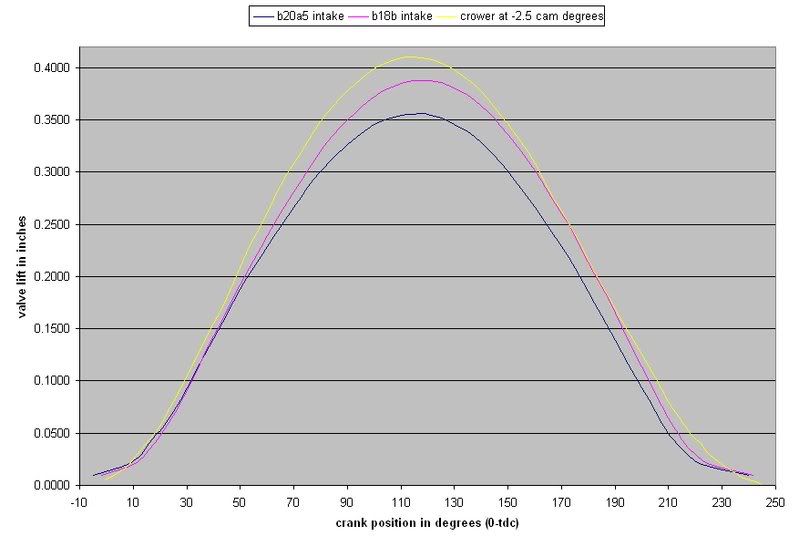

crower regrind intake cam retarded 2.5 cam degrees (5 crank degrees), compared to b20a5 intake cam and b18b intake cam both with stock cam gears (stock timing).

![Image]()

as you can see, the exhaust cam is best left at stock timing. either by using a stock cam gear, or by keeping the adjustable cam gear at zero.

the intake cam however i feel is best when set to -2.5 (2.5 cam degrees retarded, aka 5 crank degrees retarded).

the exhaust cam i feel has too much lift though for the duration it has, as well as too much lift for being used with the intake cam.

if the exhaust cam had a bit less lift, while everything else stayed the same, these would be a great true stage 1 type cam. very streetable with a very good idle at 1000 rpms, yet a good noticeable increase in power.

for those that dont know, i did a full street tune on secluded's stock b20a with these cams and a b21 intake manifold and pacesetter header and exhaust, and it pulled very well with awesome throttle response. not balls to the wall power, but a heck of a noticeable increase from stock cams

specs:

intake:

duration:

233 degrees @ 0.010" valve lift

222 degrees @ 0.020" valve lift

213.5 @ 0.030"

207 @ 0.040"

200 @ 0.050"

peak lift: 0.410" at 108 degrees ATDC

exhaust:

duration:

257 degrees @ 0.010" valve lift

243.5 @ 0.020"

231 @ 0.030"

222 @ 0.040"

215 @ 0.050"

peak lift: 0.438" at 108 degrees BTDC

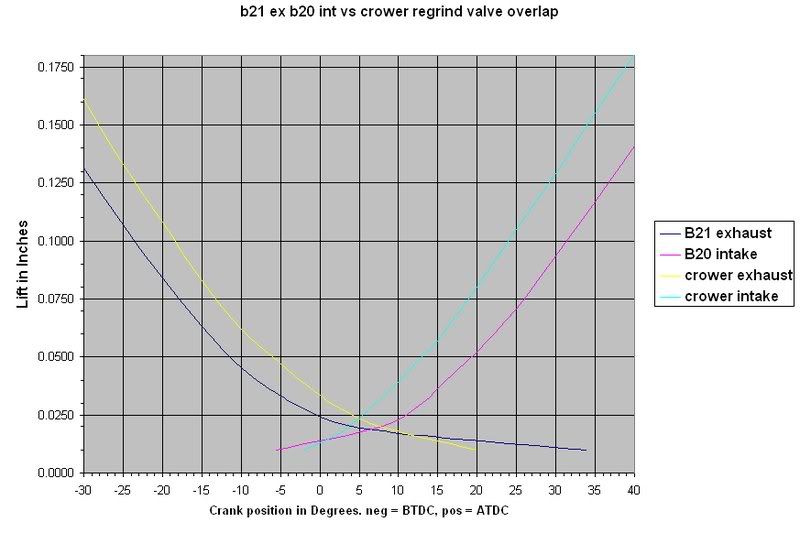

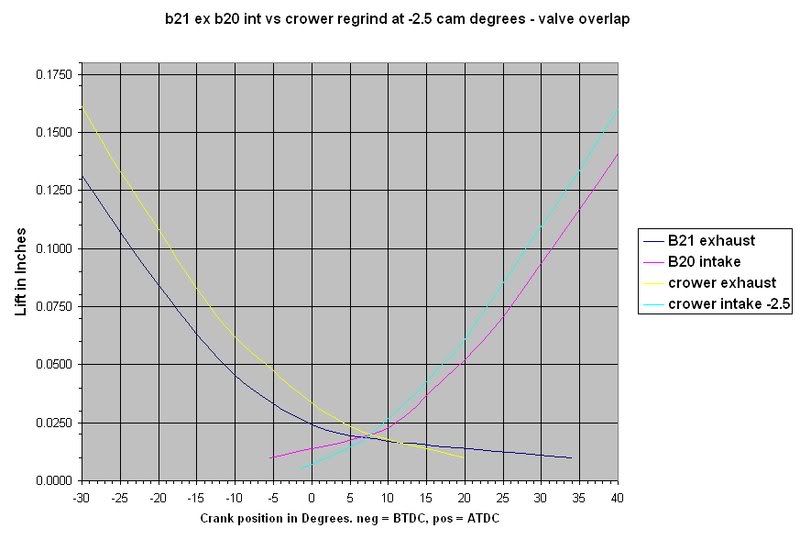

and heres some charts as requested by secluded luder of the overlap period. it is being compared to a b21 exhaust cam and a b20a5 intake cam. first pic is with the crowers both at 0, the second is with the crowers at -2.5/0 in/ex as previously reccommended according to the entire profile of the cams:

![Image]()

![Image]()

within 2 weeks, i'll be speccing and posting charts and measurements for Web Cams's grind #13 for the 3g lude. i have the cams in hand, just need to find the time to spec them and enter the info in excel. keep an eye out for them!

as for the way i set the motor up, i only installed rockers for each cam for the number 1 cylinder. no rockers in any other cyl. means much less resistance for turning the crank. all bearing surfaces were cleaned and oiled with fresh oil, bearings are from a used motor but within specs according to the manual. a few cc's of oil was dripped onto all cam bearing surfaces before caps were put on. a few cc's of oil was dripped onto each cam lobe for cyl 1. timing belt was set extremely tight by pushing very hard on the tensioner as i tightened the tensioner bolt. the 4 rockers were adjusted to 0.0005-0.0010 inches of clearance, to simulate a warmed up motor.

the b20a5 cams have about 80k miles on them

the b21a1 cams have about 117k miles on them

the head has never been shaved at all, block has never been shaved at all, and the block to head clearance (HG thickness) was set to 1.200mm (stock HG thickness when crushed under proper torque). this thickness was achieved by the use of a double layer of make-a-gasket intake gasket material. uncrushed it is 0.8mm thick, doubled up 1.6mm. crushed under proper torque worked out perfectly to 1.2mm.

i determined exact timing at lifts of: 0.010", 0.020", 0.030", 0.040", and the universal 0.050".

i also determined exact lift accurate to within 0.0005" for every 5 degrees between the above lift open and close points

i also determined exact timing of max lift. which is also known as the lobe center.

i did the entire process twice per valve to guarantee no mistakes, or variations in results. 2 cams, 2 valves per cam = 4 valves. twice per valve, means i ran this entire process 8 times. never was there any variations in numbers between any of the 8 processes. so you can be assured all numbers are 100% accurate.

i have all exact lift measurements for each cam in seperate microsoft excel files, along with the original graphs. if anyone would like me to transfer the excel documents containing all the actual numbers and information to them, please pm me through the site, or better yet send me an instant msg through aim/aol yahoo or msn via the little buttons/icons below my name to the left. i would be happy to share all info. putting all of the info in this thread would take quite a while, and take up an aweful lot of space for one post.

pics of the setup mid-progress. notice the sky blue lude without a rear bumper or bumper bracket off to the side? thats my project car, and probably the only pic of it most of you will see for quite a while

ok, now on to the part you've all been waiting for, the specs.

ATDC = after top dead center

BTDC = before top dead center

TDC = top dead center

BDC = bottom dead center

all degree numbers are in crank degrees

all measurements were taken in inches

b20a5 cams:

intake cam:

open point: (@ the following lift at the valve)

0.010" 5.5 degrees BTDC

0.020" 8 degrees ATDC

0.030" 13 degrees ATDC

0.040" 16 degrees ATDC

0.050" 19 degrees ATDC

close point: (@ following lift at the valve)

0.010" 241 degrees ATDC

0.020" 222 degrees ATDC

0.030" 217 degrees ATDC

0.040" 213 degrees ATDC

0.050" 210 degrees ATDC

duration (@ following lift at the valve)

0.010" 246.5 degrees

0.020" 214 degrees

0.030" 204 degrees

0.040" 197 degrees

0.050" 191 degrees

max lift:

0.356" @ 118 degrees ATDC

0.209" lobe lift

lobe center:

114.5 degrees ATDC

valve lift @TDC:

0.0135"

exhaust cam:

open point: (@ following lift at the valve)

0.010" 244 degrees BTDC

0.020" 225 degrees BTDC

0.030" 219 degrees BTDC

0.040" 215 degrees BTDC

0.050" 212 degrees BTDC

close point: (@ following lift at the valve)

0.010" 37 degrees ATDC

0.020" 0 degrees, perfect TDC

0.030" 6.5 degrees BTDC

0.040" 10 degrees BTDC

0.050" 13.5 degrees BTDC

duration (@ following lift at the valve)

0.010" 281 degrees

0.020" 225 degrees

0.030" 212.5 degrees

0.040" 205 degrees

0.050" 198.5 degrees

max lift:

0.366" @110 degrees BTDC

0.215" lobe lift

lobe center:

113 degrees BTDC

valve lift @TDC:

0.020"

valve overlap: (@ following lift at the valve)

0.010" 42.5 degrees

0.020" negative 8 degrees

0.030" negative 19.5 degrees

0.040" negative 26 degrees

0.050" NEGATIVE 32.5 degrees!!! (HOLY FRICKIN CRAP MAN!!!! THIS VALVE TIMNG BLOWS MAJOR BUTTHOLE!!!!!)

here are graphs of all data points collected. the concept of these graphs is to as best as possible portray the profile of the cam lobes. again, if you would like the actual microsoft excel documents containing all actual information (tables and graphs) contact me and i'd be happy to send them to you:

the thick horizontal black line is the marker for the universal open/close point at 0.050" lift

left side of each graph is where valve begins to open, right side is where valve closes.

dont mind the negative numbers in the exhaust graph, it's the only way i could get the data to line up properly in the graph.

to the left if the blue TDC line is degrees BTDC, to the right of the blue TDC line is degrees ATDC, for both graphs. 0 degrees = TDC

if you're unable to read it, the red line is "max lift aka lobe center", blue line is "TDC", green line is "BDC"

b21a1 cams:

intake cam:

open point @ following lift at the valve:

0.010" 6 degrees BTDC

0.020" 8 degrees ATDC

0.030" 13 degrees ATDC

0.040" 17 degrees ATDC

0.050" 20 degrees ATDC

close point: @ following lift at the valve

0.010" 236 degrees ATDC

0.020" 220.5 degrees ATDC

0.030" 214 degrees ATDC

0.040" 210.5 degrees ATDC

0.050" 207.5 degrees ATDC

duration: @ following lift at the valve

0.010" 242 degrees

0.020" 212.5 degrees

0.030" 201 degrees

0.040" 193.5 degrees

0.050" 187.5 degrees

max lift:

0.3465" @ 115 degrees ATDC

0.204" lobe lift

lobe center:

114 degrees ATDC

valve lift at TDC:

0.013"

exhaust cam:

open point: @ following lift at the valve

0.010" 242.5 degrees BTDC

0.020" 226.5 degrees BTDC

0.030" 220 degrees BTDC

0.040" 216.5 degrees BTDC

0.050" 213.5 degrees BTDC

close point: @ following lift at the valve

0.010" 34 degrees ATDC

0.020" 4 degrees ATDC

0.030" 3.5 degrees BTDC

0.040" 8 degrees BTDC

0.050" 11.5 degrees BTDC

duration: @ following lift at the valve

0.010" 276.5 degrees

0.020" 230.5 degrees

0.030" 216.5 degrees

0.040" 208.5 degres

0.050" 202 degrees

max lift:

0.3815" @110 degrees BTDC

0.224" lobe lift

lobe center:

112.5 degrees BTDC

valve lift at TDC:

0.024"

valve overlap: (@ following lift at the valve)

0.010" 40 degrees

0.020" 4 degrees

0.030" NEGATIVE 16.5 degrees

0.040" NEGATIVE 25 degrees

0.050" NEGATIVE 31.5 degrees

now for the graphs of the lift of each b21 cam:

the thick horizontal black line is the marker for the universal open/close point at 0.050" lift

left side of each graph is where valve begins to open, right side is where valve closes.

dont mind the negative numbers in the exhaust graph, it's the only way i could get the data to line up properly in the graph.

to the left if the blue TDC line is degrees BTDC, to the right of the blue TDC line is degrees ATDC, for both graphs. 0 degrees = TDC

b18b1 cams:

intake cam:

open point: (@ the following lift at the valve)

0.010" 2 degrees BTDC

0.020" 10 degrees ATDC

0.030" 14.5 degrees ATDC

0.040" 18 degrees ATDC

0.050" 20 degrees ATDC

close point: (@ following lift at the valve)

0.010" 242 degrees ATDC

0.020" 225 degrees ATDC

0.030" 220 degrees ATDC

0.040" 216 degrees ATDC

0.050" 213.5 degrees ATDC

duration (@ following lift at the valve)

0.010" 244 degrees

0.020" 215 degrees

0.030" 205.5 degrees

0.040" 198 degrees

0.050" 193.5 degrees

max lift:

0.388" @ 118 degrees ATDC

0.228" lobe lift

lobe center:

117 degrees ATDC

valve lift @TDC:

0.012"

exhaust cam:

open point: (@ following lift at the valve)

0.010" 259 degrees BTDC

0.020" 225 degrees BTDC

0.030" 219 degrees BTDC

0.040" 215 degrees BTDC

0.050" 212 degrees BTDC

close point: (@ following lift at the valve)

0.010" 15 degrees ATDC

0.020" 6 degrees BTDC

0.030" 12 degrees BTDC

0.040" 15 degrees BTDC

0.050" 18.5 degrees BTDC

duration (@ following lift at the valve)

0.010" 274 degrees

0.020" 219 degrees

0.030" 207 degrees

0.040" 200 degrees

0.050" 193.5 degrees

max lift:

0.3485" @115 degrees BTDC

0.205" lobe lift

lobe center:

115 degrees BTDC

valve lift @TDC:

0.017"

now on to the fun part, the comparison of each cam. the following are graphs on the cams together so you can see the direct relation of one to the other.

notice how the b20a5 intake cam has ever so slightly more lift then the b21a1 cam throughout the duration, but about the same duration time length.

also notice the b21a1 exhaust cam has a decent amount more lift then the b20a5 exhaust cam throughout the duration, and a slightly noticeable longer duration then the b20a5 exhaust cam.

the graph makes it easier to see. and even though it doesnt look like too too much in the graph, in cam terms, the difference performance-wise is fairly considerable.

removed the old comparison graphs, and added these new ones that include all 3 cams in each graph. i think the graphs speak for themselves. enjoy!!!

b18a1 cams:

today i got all the same data on b18a1 cams. i got a few basic specs on the b18a1 exhaust cam and it is almost identical to the b20a5 exhaust cam, so it would be pointless to get all data and graph it and compare it and everything else. and at the cost to modify a b18 exhaust cam to fit our motors, it's really pointless. so no major data was collected for the b18a1 exhaust cam, and no graphs were created.

the b18a1 intake cam is 99.9% identical to the b18b1 intake cam, except the fact that the entire lobe is shifted about 5 degrees. in other words, all duration and lift specs are identical between the b18a1 and b18b1 intake cam, but the b18b1 intake cam is advanced 5 crank degrees more than the b18a1 intake cam.

this means that you can use a b18a1 or a b18b1 intake cam in your 3g and get about the same results. if you get a b18a1 intake cam, it would be a good idea to get adjustable cam gears to advance it to get it even with a b18b1 cam, or advance it further to aim towards a little more overlap. aka not so far into the negatives lmao. to get the b18a1 cam even with the b18b1 cam as far as exact timing, you would set the cam gear to +2.5, because 2.5 cam degrees equals 5 crank degrees.

here is a comparison graph of the b18a1 and b18b1 intake cams to display the exact specs on both cams. i think the graph is pretty self explanatory.

b20a cams:

today i was able to get all the usual data on a set of jdm b20a cams, thanks to secluded luder for providing them for testing. i was shocked when i looked over the results, and especially shocked when i graphed them. well, kind of a mix between seeing what i expected for one, and something totally unexpected for the other. due to the graphic nature of this program viewer discretion is advised lmao! actually, due to the results of the data collected, im not going to bother posting the actual info on them as i have for the above other cams. to sum it up, the jdm b20a intake cam is 100% identical to the USDM b20a5 intake cam. the jdm b20a exhaust cam is similar to the b20a5 exhaust cam, but a bit worse. to further explain and see the similarities, simply lok at the following graphs; they show all:

sorry to disappoint you guys lol

b20a5 overlap:

(@ following lift at the valve)

0.010": 42.5 degrees

0.020": negative 8 degrees

0.030": negative 19.5 degrees

0.040": negative 26 degrees

0.050":negative 32.5 degrees

b20a5 overlap with gears set to +4/-4:

(@ following lift at the valve)

0.010": 58.5 degrees

0.020": 8 degrees

0.030": negative3.5 degrees

0.040": negative10 degrees

0.050":negative 16.5 degrees

b21a1 overlap:

(@ following lift at the valve)

0.010": 40 degrees

0.020": 4 degrees

0.030": negative 16.5 degrees

0.040": negative 25 degrees

0.050": negative 31.5 degrees

b21a1 overlap with gears set to +4/-4:

(@ following lift at the valve)

0.010": 56 degrees

0.020": 20 degrees

0.030": negative 0.5 degrees

0.040": negative 9 degrees

0.050": negative 15.5 degrees

b21 ex b20a5 int overlap:

(@ following lift at the valve)

0.010": 39.5 degrees

0.020": negative 4 degrees

0.030": negative 16.5 degrees

0.040": negative 24 degrees

0.050": negative 30.5 degrees

b21 ex b20a5 int overlap with gears set to +4/-4:

(@ following lift at the valve)

0.010": 55 degrees

0.020": 12 degrees

0.030": negative 0.5 degrees

0.040": negative 8 degrees

0.050": negative 14.5 degrees

b21 ex b18b int overlap:

@the following lifts at the valve:

0.010": 32 degrees

0.020": negative 6 degrees

0.030": negative 18 degrees

0.040": negative 26 degrees

0.050": negative 31.5 degrees

b21 ex b18b int overlap with gears set to +4/-4 in/ex:

@the following lifts at the valve:

0.010": 48 degrees

0.020": 10 degrees

0.030": negative 2 degrees

0.040": negative 10 degrees

0.050": negative 15.5 degrees

b21 ex b18a int overlap:

@the following lifts at the valve:

0.010": 36 degrees

0.020": negative 10 degrees

0.030": negative 22 degrees

0.040": negative 30 degrees

0.050": negative 36 degrees

b21 ex b18a int overlap with gears set to +4/-4 in/ex:

@the following lifts at the valve:

0.010": 52 degrees

0.020": 6 degrees

0.030": negative 6 degrees

0.040": negative 14 degrees

0.050": negative 20 degrees

added july 12 2006, updated july 15 2006:motoxxxman before posting the b21 results and comparisons said:

suggested cam specs for regrinds:

keep in mind these figures are given with the lift point being at the valves, not at the cams. so these are not a direct translation to simply hand over to a re-grinder.

i will translate them into specs that you CAN simply hand to a re-grinder sometime in the near future i hope.

stage 0.5:

b20a5 intake cam

b21a1 exhaust cam

stage 0.9:

in: 193.5 degrees duration @ 0.050" valve lift, 0.388" max lift (b18b intake cam, uncertain for now)

ex: 202 degrees duration @ 0.050" valve lift, 0.382" max lift (b21a1 exhaust cam)

stage 1:

in: 201 degrees duration @ 0.050" valve lift, 0.400" max lift

ex: 202 degrees duration @ 0.050" valve lift, 0.382" max lift (b21a1 exhaust cam)

stage 2:

in: 198 degrees duration @ 0.050" valve lift, 0.415" max lift

ex: 203 degrees duration @ 0.050" valve lift, 0.405" max lift

stage 3:

in: 204 degrees duration @ 0.050" valve lift, 0.430" max lift

ex: 204 degrees duration @ 0.050" valve lift, 0.420" max lift

stage 4:

in: 208 degrees duration @ 0.050" valve lift, 0.440" max lift

ex: 206 degrees duration @ 0.050" valve lift, 0.430" max lift

i could create a stage 5 if anyone wants to know

turbo cams (any type of turbo setup):

in: 205 degrees duration @ 0.050" valve lift, 0.465" max lift

ex: 202 degrees duration @ 0.050" valve lift, 0.465" max lift

stage 2 is recommended for street and strip and various speed track racing.

stage 3 is suggested for all out racing (mostly higher speed track, and drag), but can be used on the street with some minor discomfort in typical driving situations at lower rpms, and may not idle at stock idle speeds. crap power below 3k, decent 3k-4500, great/wicked power 4500-7200

stage 4 is full out 100% race only; high speed only track racing, and all out drag. basically meaning that with stage 4 the engine will be tough to start initially, and it WILL NOT IDLE below 1500-2k or so; and you will have crap for power below 4500, good power 4500-~5800, and wicked power 5800-7200

i have officially determined max allowable lift at the valves with the stock valvetrain; aka springs and retainers.

maxed out at: 0.487"

my recommended max limit: 0.450"

my recommended max SAFE limit: 0.440"

so basically, if you want to go with more then 0.440" of lift i highly suggest you get aftermarket springs and retainers that will allow that much lift. if you want to go more then 0.450" of lift, you will NEED to get aftermarket springs and retainers that will allow that lift.

update: 1/04/08:

jdm b21a cams are practically identical to the usdm b21a1 cams i previously measured.

ludasaurus was kind enough to ship me a set of jdm b21a cams to spec.

im not gonna bother making charts and diagrams and everything for them cuz they are almost 100% identical to the usdm b21a1 cams. like 0.001" difference in valve lift at a couple random points, thats about the only difference, which is nothing, more than that could happen just from wear and/or user error

update 05/12/08:

i specc'ed and charted secluded luder's crower regrinds for the 3g prelude, which were discontinued a few years back. but here they are:

exhaust cam compared to b20a5 and b21a1 exhaust cams, all 3 spec'ed with stock cam gears:

crower regrind intake cam compared to b20a5 intake cam and b18b intake cam, all spec'd with stock cam gears:

crower regrind intake cam retarded 2.5 cam degrees (5 crank degrees), compared to b20a5 intake cam and b18b intake cam both with stock cam gears (stock timing).

as you can see, the exhaust cam is best left at stock timing. either by using a stock cam gear, or by keeping the adjustable cam gear at zero.

the intake cam however i feel is best when set to -2.5 (2.5 cam degrees retarded, aka 5 crank degrees retarded).

the exhaust cam i feel has too much lift though for the duration it has, as well as too much lift for being used with the intake cam.

if the exhaust cam had a bit less lift, while everything else stayed the same, these would be a great true stage 1 type cam. very streetable with a very good idle at 1000 rpms, yet a good noticeable increase in power.

for those that dont know, i did a full street tune on secluded's stock b20a with these cams and a b21 intake manifold and pacesetter header and exhaust, and it pulled very well with awesome throttle response. not balls to the wall power, but a heck of a noticeable increase from stock cams

specs:

intake:

duration:

233 degrees @ 0.010" valve lift

222 degrees @ 0.020" valve lift

213.5 @ 0.030"

207 @ 0.040"

200 @ 0.050"

peak lift: 0.410" at 108 degrees ATDC

exhaust:

duration:

257 degrees @ 0.010" valve lift

243.5 @ 0.020"

231 @ 0.030"

222 @ 0.040"

215 @ 0.050"

peak lift: 0.438" at 108 degrees BTDC

and heres some charts as requested by secluded luder of the overlap period. it is being compared to a b21 exhaust cam and a b20a5 intake cam. first pic is with the crowers both at 0, the second is with the crowers at -2.5/0 in/ex as previously reccommended according to the entire profile of the cams:

within 2 weeks, i'll be speccing and posting charts and measurements for Web Cams's grind #13 for the 3g lude. i have the cams in hand, just need to find the time to spec them and enter the info in excel. keep an eye out for them!